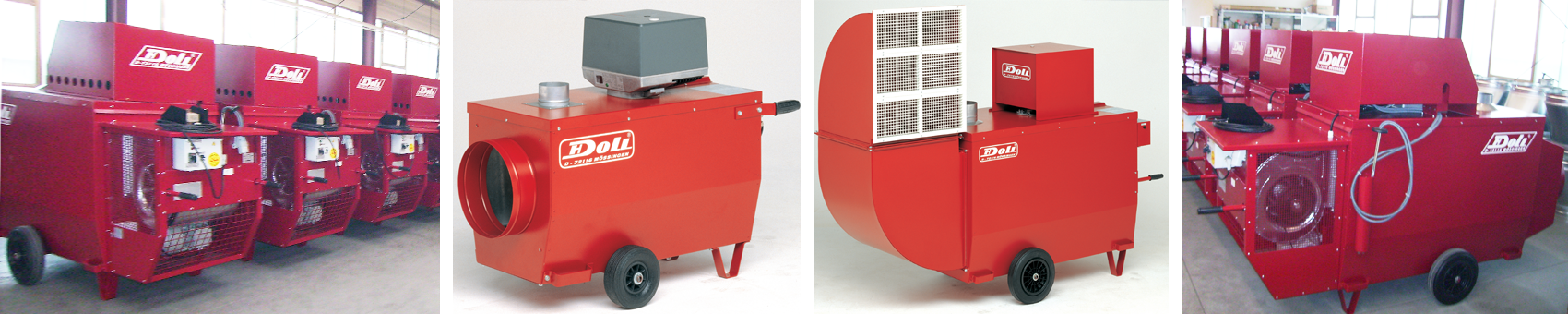

Mobile Heating Devices

Trendsetting technology with novel combustor and recuperator geometry for the energy-saving heating and aeration of industry halls, craft halls, tents, construction site heating and drying.

In the case of a stronger pressing or priming is desired, for instance when using film-tube distribution, all devices are available in specifically customised completion with high-pressure ventilators.

In the case of a stronger pressing or priming is desired, for instance when using film-tube distribution, all devices are available in specifically customised completion with high-pressure ventilators.

- ranging from 20 to 150 KW heating power... and 1450 up to 11000 m³/h air-throughput

- universal system for indoor and outdoor operation - fully automatic

- autonomous •space saving

- all devices are available for film-tube-connector or long-range-distributor (utility patent / CH-patent).

Technische Daten

| Typ | Heizleistung | Luftleistung |

| K 20 HD | 20 kW | ~1450 m³ / h |

| K 30 HD | 34 kW | ~2300 m³ / h |

| K 50 HD | 54 kW | ~5050 m³ / h |

| K 70 HD | 70 kW | ~5550 m³ / h |

| K 103 HD | 110 kW | ~9800 m³ / h |

| K 103 HD-S | 150 kW | ~11000 m³ / h |

The comparative advantages at a glance :

- mobile but features all advantages of a stationary unit, high performance fitted in a compact + practical construction.

- containing both: heater + aeration device for applying jack at 230 V / 50 Hz and fully automatic with thermostat controller connector.

- automated heating of the oil filter regarding all systems up to K70HD (from device K103H - available as accessory).

- barely no servicing + maintenance friendly.

- exhaust fume lines completely accessible.

- combustor and recuperator made of special stainless steel.

- K20HD V self-cleaning function made possible by vertical plate recuperator.

- connectable to exhaust pipes.

- on top situated downthrow track burner excluded from dusty-area.

- high performance burner from Elco or Weishaupt completely mounted and calibrated.

- casing robust and and free from torsion effects.

- protected from corrosion: fully zinc-coated + plastic coated.

- designed in double-walled completion for recycling radiation heat.

- two stable handles, two carrying handles, four crane ears.

- end-to-end design with welded U-profile axis.

- wide and high vulcanised rubber tyres.

- serially equipped with needle beared tyres from K 70 .

- capable of connecting oil-supply line - single or double string.

- external rotor ventilator with encapsulated motor.

- electr. fan motor protected by the use of a thermo relay.

- high performance air-throughput with low level acoustic emissions.

- switching board with operation and switching lamps.

- safety temperature limiter - inherently safe.

- electrical controlling + adjusting devices mounted protectively in the switching cabinet.

- connection possible with a combustor burner protective case.

- German DIN standardisation parts and components.

- operation with no exhaust line attached, connection available for hot air film tubes or Doll- long range air distributor.